Why ATV Belts Fail and How You Can Prevent It

Only you can prevent premature belt failure

Any off-roader worth their salt has had to deal with a thrown belt or two out on the trail. Whether this downtime was caused by an over-exuberant use of the throttle or a simple lack of maintenance is completely dependent on your style of riding and vehicle upkeep.

(Hint: it’s definitely throttle use for most of us here in the ATV.com office.)

Luckily, the crew at Gates know a thing or two about belts for powersports machines, setting up shop in Colorado over 100 years ago and becoming a leading manufacturer of power transmission products. Their latest research has led to the development of the new G-Force RedLine series of CVT belts, featuring a unique, patented compound that handles extreme temperatures (exceeding 330 degrees) and adds stiffness, enabling the belt to run at higher loads for longer amounts of time.

In other words, these G-Force RedLine belts will give you one less thing to worry about when caning your ATV during a day on the trail with your buddies.

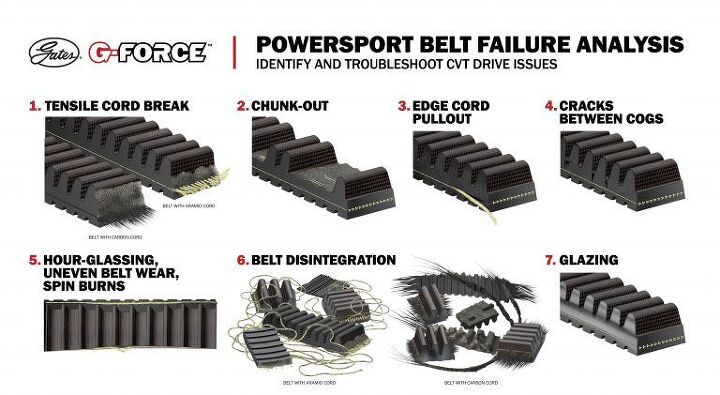

But why do belts fail in the first place? Gates has helpfully identified seven distinct types of failures. The cause of these failures can be grouped into a few distinct categories, including the aforementioned prime suspect for many of us: excessive throttle use.

Bad Driving Habits

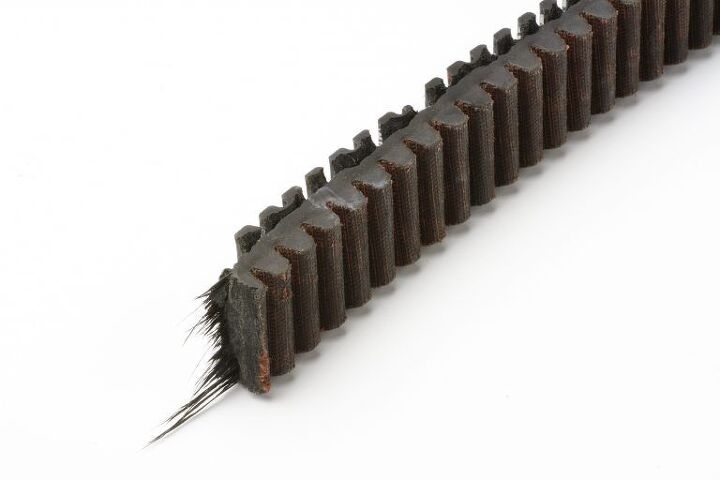

We’ll start with this one because it’s arguably the most common, but also the easiest to remedy. Sudden and aggressive engagement RPM (neutral drops, anyone?) can lead to a tensile cord break, the type of failure in which the belt is literally ripped in half. Good quality belts, like the G-Force RedLine, are strengthened with carbon or aramid cords but even kryptonite is unlikely to withstand the most boneheaded of throttle applications.

Belt disintegration, AKA when a belt has broken into several smaller pieces, can happen thanks to repeated shock-loading or excessive belt speed. Intense heat buildup caused by extreme driving conditions – like when your machine is stuck in mud or sand with ample wheel spin – doesn’t help, either.

Uneven belt wear, or hour-glassing, is also a product of wide-open get unstuck now throttle behavior, but can also occur if a machine is left idling for extended periods. Similarly, a belt that looks melted or shiny could be the product of excessive and abrupt acceleration.

Improper Maintenance

Not all belt problems are a result of bonehead driving, believe it or not. Improper maintenance, or a complete lack thereof, can also cause a world of issues. Removing a couple of ribs doesn’t just happen when your buddies show up and grab more than their share off the grill—it can also happen to ATV belts. This is sometimes called ‘chunk-out,’ and no, it doesn’t mean your belt needs to drop a few pounds. It means it needs to be replaced.

If a belt is improperly installed or back-bent before being put on the machine, it can fracture and cause some of its ribs/cogs to make a bid for freedom. This will leave spaces on the belt emptier than your beer supply after Sunday night football. It is alarmingly easy to unknowingly stress a belt in this manner during installation, given the gymnastics required on some engines to wrestle a new belt into place.

Cords appearing on the edge of your belt can also be caused by improper installation, perhaps by a clutch misalignment or incorrect pulley angles. Cracks between the cogs are a sure sign of a belt that’s older than you are, or one that was bent into unnecessary shapes during very cold weather.

Clutch Issues

So you practice proper driving habits and keep your machine in good working order… Unfortunately, you can still experience common issues like belt disintegration (shown below) and hour-glassing, and the culprit could be a misaligned or improperly tuned clutch. If you’ve made any modifications to your ATV — such as adding weight, increasing your tire size, or changing your tire style — without ensuring your clutches are properly aligned, you could experience the same sort of uneven wear mentioned above.

This includes that melted, shiny look known as “glazing” — and while a nice glaze may look great on ham, you want to avoid it at all costs on an ATV belt. Always verify you’ve got the correct belt for your intended application and be sure your clutches are correctly tuned if you’ve recently added vehicle weight or upgraded your tires (especially if you’ve changed your tire size).

Storage Issues

Yes, some belt problems can be traced back all the way to how they’re stored after manufacture. While it’s true there isn’t much we can do as customers about how belts are handled by a pimply-faced teenager manning a service desk, we can take the proper care once the new belt is in our possession – especially if it is serving as a spare. You do keep a spare belt in your rig, right? Right?

There’s never a reason for turning a belt inside out, at least not one that has to do with proper storage of the thing. Needless back-bending doesn’t help matters, nor does twisting it into new and interesting shapes in an effort to stuff it into a storage compartment that’s simply too small. Keeping a spare belt clean seems obvious but isn’t always top of mind, so give it the once-over prior to hitting the trails.

So there you have it. Practicing proper attention and care (both on and off your machine) can help prevent premature belt failure and all the headaches that come with it. And if you do end up having to replace a broken belt, always remember to properly break in your new belt before installing.

To learn more about Gates G-Force RedLine series, click here, then visit Navigates.Gates.com to find the right Gates belt for your vehicle.

More by Sponsored Post

![Derek Guetter Crashes During Backflip [video]](https://cdn-fastly.atv.com/media/2022/10/24/8744073/derek-guetter-crashes-during-backflip-video.jpg?size=350x220)